![]()

Web-Based Practice

Environments to Teach Mechanical Skills

Janet

Faye Johns,

The MITRE Corporation

Abstract

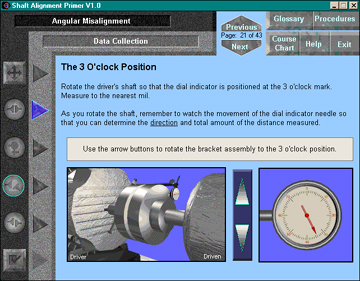

This paper demonstrates 3-Dimensional

(3-D) practice environments developed to teach mechanical skills. The

instructional strategy integrates multimedia Computer-Based-Training (CBT)

with a structured 3-D practice environment and a virtual 3-D practice

environment. The entire multi-layered application can be delivered via

Web browsers on a corporate local area network (LAN) or on the Internet.

The multimedia CBT and structured 3-D practice environment were implemented

for traditional CBT delivery and were converted to Web delivery. The virtual

practice environment is a desktop Virtual Reality 3-D space that was implemented

with the Virtual Reality Modeling Language (VRML) and Java for Web delivery.

Realism is added to the multimedia CBT and practice environments by using

3-D Computer Aided Design (CAD) models as the source for images, animations,

and user-controlled objects.

1.

Instructional Strategy

Training mechanical skills requires developing the cognitive, perceptual, and motor skills of the student. The student must be taught to visualize the complex relationships between mechanical components, diagnose problems, and perform corrective actions. Demonstrations, simulations, performance-based laboratory exercises, and on-the-job-training (OJT) in an apprenticeship program are typically used to teach mechanical skills. These techniques emphasize the development of motor skills but do not adequately address the perceptual skill development needed to become an expert.

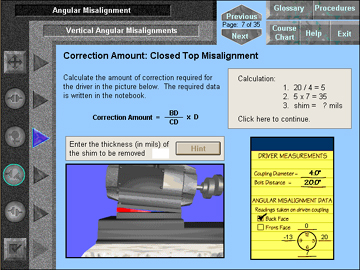

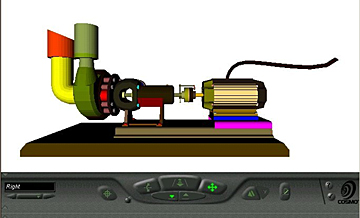

Multimedia CBT techniques with realistic 3-D practice environments appear to offer a natural solution for improving the perceptual skills of students. Practice is extremely important in the development of perceptual and mechanical skills. Perceptual skills are improved by giving the student a practice environment to explore and experiment with the mechanical system. The instructional strategy is shown in Figure 1.

![]()